Adaptation of the condensation and hydrodeoxygenation process in a continuous reactor

One of the main objectives of the HIGFLY project is to demonstrate a scalable technology for biofuel production from furfural and bio-oxygenates derived from sustainable biomass feedstocks.

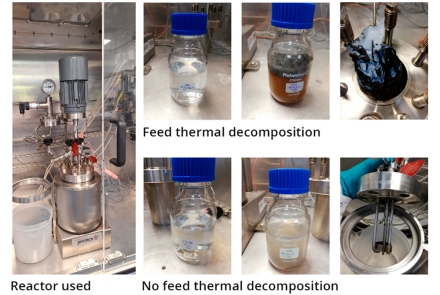

To help achieve this objective, TNO and Fraunhofer have focused on the validation of catalyst stability under long continuous operation, which was assessed by evaluating the performance and activity of the developed catalytic systems for at least 100 hours of continuous operation. The goal is to assess the catalysts' ability to maintain their activity over an extended period of time, which is crucial for the successful implementation of the biofuel production process.

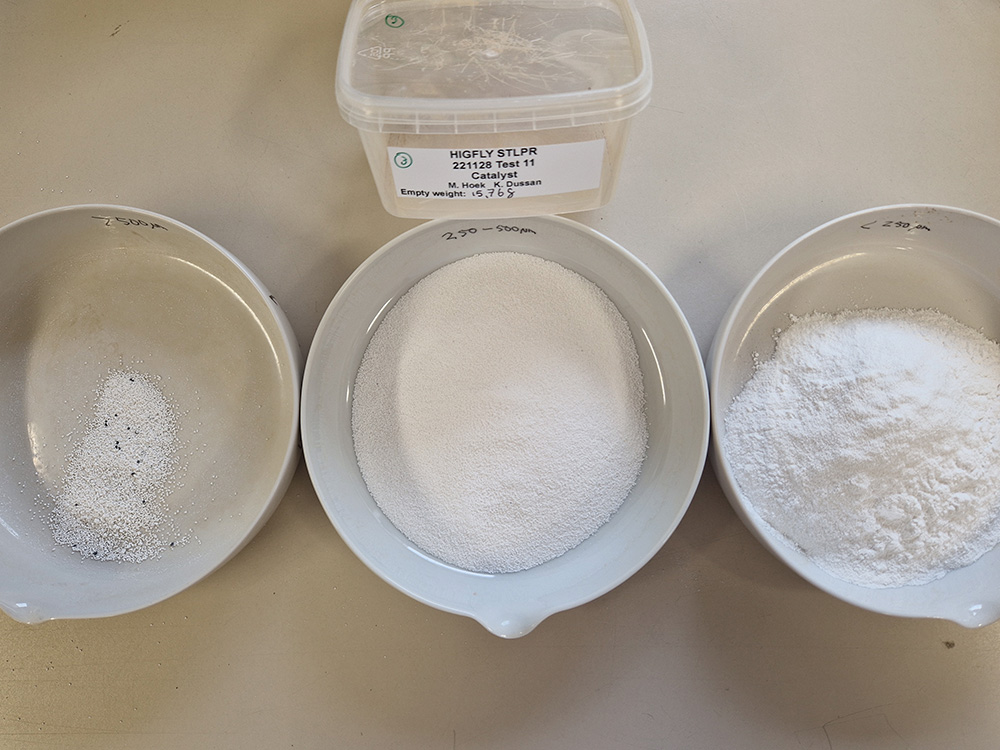

Building on the development of a catalytic process for the hydrodeoxygenation of condensed intermediates that aimed to enhance the production of oxygen-free fuel samples, recent research investigated the regeneration of catalysts used in the liquid and gas phase condensation processes. Laboratory experimentation involved testing various regeneration protocols on the spent catalysts and analysing their properties and performance. The results showed that calcination was effective in removing deposited carbon on the catalysts. The regenerated catalysts exhibited higher surface areas and improved CO2 uptake (indicative of basicity) compared to the fresh catalysts. However, the regeneration process also led to changes in catalyst activity and selectivity.

Lessons Learnt

The main lessons gained from this research were that the issue of catalyst deactivation attributed to carbon deposition during condensation processes significantly hampers catalyst activity and conversion efficiency. To counteract this, reactivation through calcination has been identified as an effective strategy, albeit with partial success.

Catalyst stability for continuous operation is hugely important. While catalysts selected for hydrodeoxygenation demonstrated sustained activity over prolonged periods, those employed in condensation processes exhibited deactivation and highlighted the need for further research and optimisation efforts.

In the liquid-phase condensation of furfural and acetone, calcination extends catalyst activity but introduces changes in conversion rates and product compositions. Understanding and managing these alterations are vital for process development activities.

In gas-phase condensation, low catalyst activity and limited conversion rates pose significant hurdles for scalability. Addressing these challenges requires the implementation of a recycle strategy and improved product separation methods to enhance conversion efficiency.

Next steps

The research by TNO and Fraunhofer demonstrates the scalability and feasibility of processes for developing technologies and materials for biofuel production from furfural and bio-oxygenates, underscoring the importance of catalyst stability, reactivation methods, and process optimisation for achieving long-term continuous operation. Insights gleaned from this research have provided invaluable guidance for future development and optimising processes for advancing the HIGFLY technologies.

The next stage will be to demonstrate the operability of the systems under realistic conditions and realistic feed capacities which will be used to characterise the catalytic properties after operation and the chemical composition of the final product. The properties of the jet fuel precursors following hydrodeoxygenation will be determined which will allow the evaluation of the potential jet fuel yield from the process, and the distillation curve, freezing point, residual oxygen content, and energy content of the obtained samples.