The separation of furfural and bio-oxygenates using novel deep eutectic solvent-based supported liquid membrane technology

HIGFLY researchers are exploring innovative techniques to enhance the purification process of biofuels. A part of this process is the use of deep eutectic solvents (DES) and supported liquid membranes (SLM) as a means of purifying jet fuel precursors, specifically furfural and bio-oxygenates.

Solvents and membranes are vital in biofuel production, serving key roles in extraction, purification, and separation processes. Within the HIGFLY project, solvents and / or membranes are used to purify the products generated from biomass feedstocks. These technologies minimise waste generation, improve energy efficiency, and enhance the scalability of biofuel production. By facilitating cleaner and renewable production processes, solvents and membranes contribute to environmental sustainability and reduce dependence on fossil fuels.

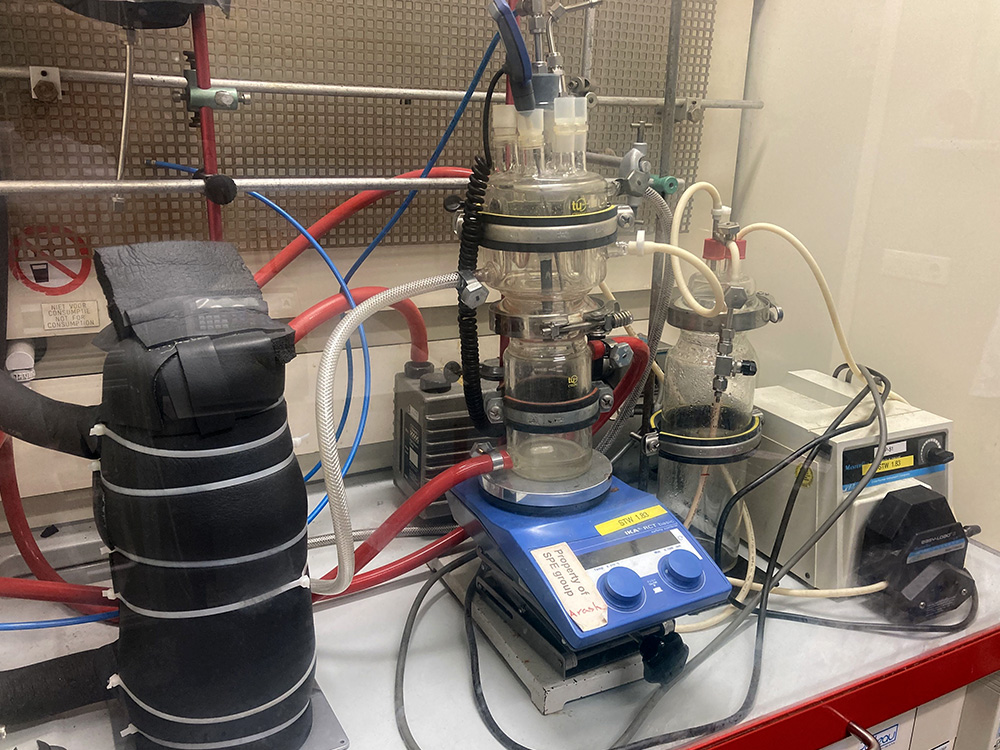

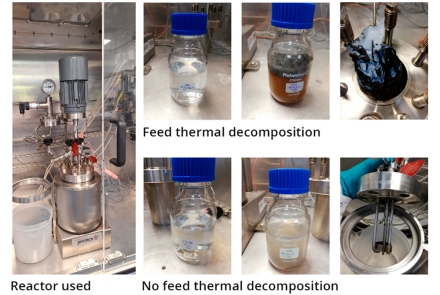

HIGFLY´s research into the use of solvents and membranes began with the synthesis of DES-based SLMs through simple impregnation methods. This involves utilising commercially available ceramic substrates and identifying optimal DES compositions. The objective is to develop membranes capable of efficiently separating furfural and bio-oxygenates from aqueous streams, a critical step in the HIGFLY process.

Combinations of DES-based SLMs were tested with an aim to assess the membranes' stability and performance in selectively extracting target compounds from complex aqueous solutions. By analysing separation efficiency and energy input, researchers evaluated the technical feasibility of DES-based SLM technology compared to conventional approaches like extraction and distillation. Additionally, the potential synergies between DES-based SLMs and traditional purification techniques to optimise the overall separation strategy were assessed.

A recent report published by Eindhoven University of Technology (TU/e) detailed their research on the selective separation of furfural using supported liquid membrane technology. The research methodology involved process simulation, testing different types of membranes, pre-selection of deep eutectic solvents, evaporation loss from different substrates, pressure testing of ceramic substrates, analysing the concentration of furfural in permeate and retentate streams, and the assessment of energy gains compared to distillation.

The main conclusions highlight the limitations in terms of evaporation, pressure resistance, and temperature operation for the use of DES-based SLMs for furfural separation but improved conventional membranes and other types of membranes show potential. Overall, the research has shown that the use of DES-based SLM technology for furfural separation is viable and has identified pathways for future areas of research and development.