HiGee Reactor Development for the Single and Two-step Synthesis of Furfural and Bio-oxygenates

Furfural is the primary jet fuel precursor and building block within the HIGFLY concept. The existing methodologies employed for converting biomass feedstocks into furfural exhibit notable inefficiencies in resource utilisation, substantial costs, and high energy consumption. These methods result in a yield of less than 50% of the potential value and a complete loss of cellulose and lignin.

Furfural is the primary jet fuel precursor and building block within the HIGFLY concept. The existing methodologies employed for converting biomass feedstocks into furfural exhibit notable inefficiencies in resource utilisation, substantial costs, and high energy consumption. These methods result in a yield of less than 50% of the potential value and a complete loss of cellulose and lignin.

In response to these challenges, HIGFLY´s research is strategically oriented towards process intensification. This is achieved through the implementation of a HiGee reactor with a high gravity, high shear design that aims to greatly increase mass and heat transfer rates and overall process intensification that surpasses the capabilities of currently available technologies.

Eindhoven University of Technology, with expertise in designing, constructing, and operating reactors, has already demonstrated through lab scale experiments and modelling work, that there is a potential for a 50-fold reduction in reactor size coupled with an increased furfural yield of up to 90%. The HiGee reactor also offers the flexibility of being packed with a coated 3D foam structure with a substantial specific surface area. The distinctive combination of a high specific surface area and the pronounced shear capability inherent in HiGee reactors facilitates efficient liquid-liquid extraction.

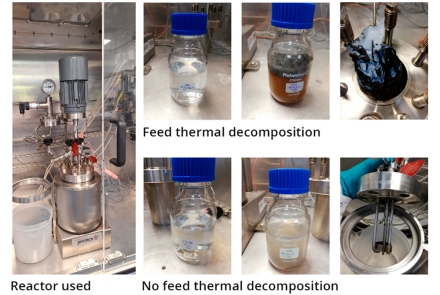

Preliminary experiments also indicated that the HIGFLY concept could mitigate the formation of black deposits (humins) within the reactor, which is a common problem with current methods of furfural sythesis. A reduction in deposits would enable longer periods of continuous operation, leading to a reduction in capital expenditures and a tangible solution to a critical bottleneck in the value chain.

A recent report produced by Eindhoven University of Technology entitled “HiGee Reactor Development for the Single and Two-step Synthesis of Furfural and Bio-oxygenates” provides updates to the progress of the HiGee reactor design and results from simulations.

The report provides insights into the latest kinetic modelling designed to identify the optimal catalyst loading, reactor temperature and flow rates of the feed. These parameters were then used to perform reactor modelling which, in turn, informs reactor design and assembly, and the selection of an optimal process integration strategy and operating conditions for the synthesis of furfural and bio-oxygenates.

The main conclusions of the report were the identification of the best performing catalyst to be used in the reactor and the optimal loading of the catalyst to maximise reaction kinetics and furfural yields. Further developments of the reactor design and assembly will be published in upcoming reports and newsletters.