Solid Catalyst Development for C5 Sugars Conversion to Furfural & Bio-oxygenates

Furfural is a valuable chemical that can be produced from biomass and is commonly used as a building block in the synthesis of various chemicals such as solvents and pharmaceuticals. However, the production of furfural from biomass-derived sugars becomes challenging due to the complexity of the feedstocks and the low selectivity of the process, where sub-products are largely formed. One possible solution to overcome this challenge is the use of solid acid catalysts.

Solid acid catalysts are commonly used within many industrial processes, such as the petroleum industry and refineries, because they are materials that can catalyse and accelerate chemical reactions in the absence of a liquid acidic species by providing acidic sites on its surface. The use of solid catalystholds several advantages including easier separation of the products from reaction mixtures through filtration alone, reduction of corrosion in reactors, better stability of the catalyst and the potential for reuse, which reduces waste and can limit the downtime of industrial operations. For furfural production specifically, solid acid catalysts can selectively catalyse the dehydration of C5 sugars (i.e., xylose) to furfural, thus allowing the valorisation of hemicellulose aqueous fractions and leaving other biomass components intact for additional exploitation.

Instituto de Tecnología Química (CSIC-ITQ), with contributions from Eindhoven University of Technology (TU/e), have submitted their report on catalyst development for C5 sugars dehydration to furfural and the hydrogenation of furfural and bio-oxygenates present in the aqueous side-streams following the dehydration step.

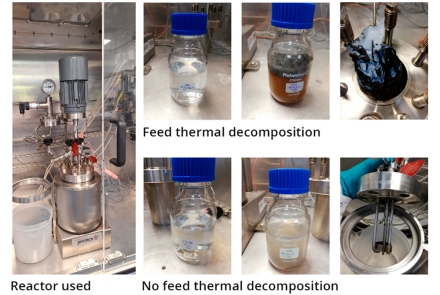

Solid acid catalysts were prepared and studied for the C5 sugar dehydration to furfural and compared with both heterogeneous and homogeneous commercial reference catalysts in autoclave-type and fixed bed continuous flow reactors systems. This was followed by a detailed catalytic screening of different metallic oxides and mixed oxides allowing the development of novel materials that, in their optimal composition, show promise as catalysts for the C5 sugar dehydration to furfural phase and were selected for further studies.

Parallel kinetic studies were carried out at TU/e with selected catalysts. The work by TU/e revealed that the presence of both Brönsted and Lewis acid sites are important to achieve high furfural yields in this reaction. Monophasic (only water and water + co-solvents) versus biphasic (water/organic solvent) systems were also assessed in auto-clave systems.

In addition, the selective hydrogenation of furfural and bio-oxygenated compounds generated during C5 sugars dehydration was thoroughly studied by both TU/e and CSIC, using metal-supported catalysts under different operational conditions. Mechanistic studies of reaction pathways were performed by using furfural and reaction intermediates as reactants. The results obtained by using both metallic and acid sites in catalysts showed that both functionalities are needed to conduce the consecutive reaction steps towards the desired hydrogenated products..

It has been determined that solid acid catalysts are a promising strategy for obtaining furfural from biomass. They offer several advantages over homogeneous acid catalysts and have been shown to be effective for furfural production. CSIC-ITQ and TU/e will conduct further research using selected solid acid catalysts in different reaction set-ups to optimize process parameters and maximize furfural production and continue developing catalytic processes for the hydrogenation of furfural and bio-oxygenates from the aqueous side-streams.